When last we met, I spun a tale that could have applied to any of us. Person wants a new headphone cable, sees prices, recovers in hospital for a week, decides to make own cable, has no idea where to start. I discussed where I started, by purchasing the tools to do the job, and perhaps some of you have followed in my footsteps.

After spending all that time and effort getting the tools to make my own cables, I was eager to start right away. And since I’m a nerd, “getting started right away” meant doing research on the internet for a few days before doing anything else.

The Prep Work

As I mentioned in my last article, I’ve found that doing the prep work is the biggest key to success in DIY. I started searching online for how to make a headphone cable and read through many great articles and tutorials. One thing that became clear is that there’s no Best Way to make a cable. In fact, there seemed to be a large component of artistic expression available for those who are into that kind of thing. While choice and options are good, I was a bit overwhelmed.

Fortunately, I already had a good idea of what I wanted. See, when I bought my LCD-2, it came with an aftermarket cable of which I really liked the look and feel. It was four thin strands, each individually sleeved in what I later learned was silk, and braided together to make a single cable. It was light and supple and looked really classy. And as a bonus, it didn’t make noise when it rubbed against my clothes like some cheap cables – it had no microphonics. I sold this cable with my LCD-2, but I wanted to make one like it for my HE-560.

With this in mind, I was able to narrow down my research and find all the information I needed to get started. This is the information I will be passing along to you. Now, let’s go shopping.

Parts List

A cable requires only two parts to work: the connectors and the cable itself. A good-looking cable will also use things like paracord sleeving and a cover for the Y-split. The cable I made eschews the cover for the Y-split in favor of a smooth transition in the braid. But I’m getting a little ahead of myself. Let’s just stick with the parts list for now.

The cable, as mentioned, will be made of four thin wires that are braided together. These wires come in many different flavors and some people believe that the type of wire you use can influence the sound traveling through them. This subject has been discussed ad nauseum and I don’t plan on commenting on it. Fortunately, I was looking for the least expensive solution that would still sound at least as good as the stock cable, which means that most of the exotic stuff was out either way.

It turns out, the best value for purchasing these wires is to actually purchase microphone cable. These cables consist of four wires twisted up, shielded and coated in rubber. The idea is that you buy this microphone cable and strip the 4 internal wires out for some great value. It adds a bit of work, but it’s by far the most cost-effective route.

There are three main mic cable manufacturers that are generally recommended: Mogami, Canare and Gotham. As far as I can tell, these are functionally equivalent and you can pretty much just get whichever floats your boat. I purchased the Canare L-4E5C at $0.48 per foot. I picked up 25 feet of this cable to have enough for a few cables and a few mess-ups. It ran me a total of $12. There’s also the Mogami W2893 and Gotham Mini Star Quad (GAC-4). Other variants will likely work just as well. I just went with the cheapest.

The next thing you need is the sleeving to cover the wires. I use paracord for this; it’s not silk, but it has no microphonics and it comes in an unbelievable variety of colors. The part that was really confusing to me at first was figuring out which size to use. It seemed that either 95# or 275# would work for me.

I tried both and I am going to recommend that you stick with the 275# paracord for a few reasons. First, it’s slightly looser, making it significantly easier to get onto the wires. It’s still tight enough that I doubt anyone would be able to tell the difference from looking. The other big thing is that the 95# paracord “shrinks” because it’s so tight. By that I mean if you put 6’ of paracord on a 6’ wire, it’s only going to cover about 5’6” of that wire. I’m not sure what the deal is with that, but the 275# doesn’t have this problem. In fact, you’ll likely have more sleeving than wire with 275.

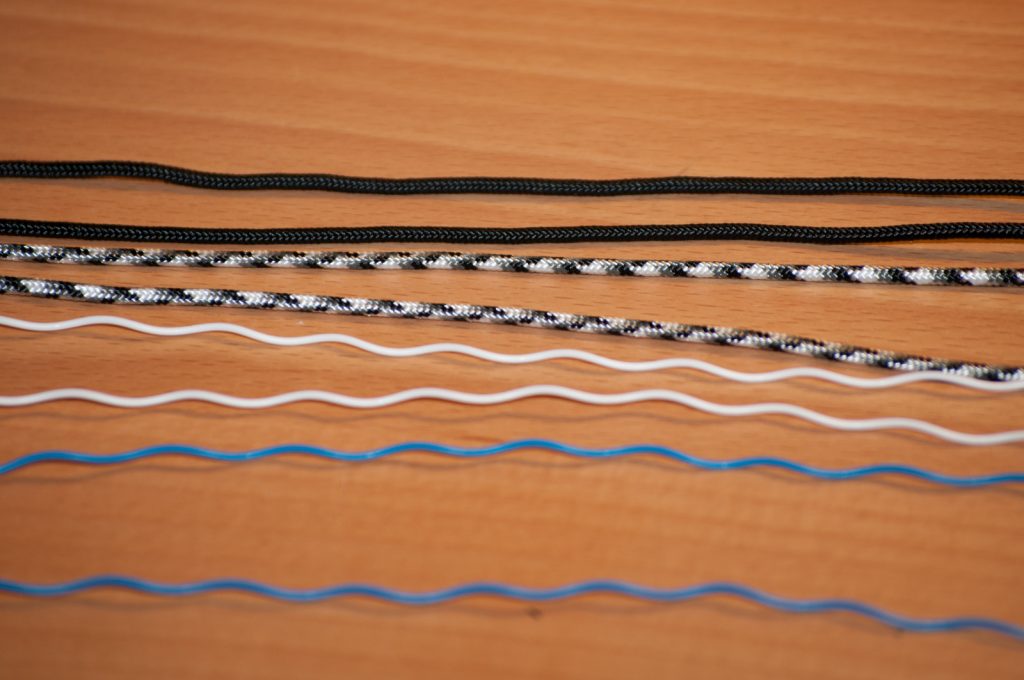

Black and “black widow” cable and adapter

The only other thing to consider when buying the paracord is what color(s) you want. I had a vision before I started my first cable: I wanted to have two black wires braided with two colored wires, then I’d have the colored pair go to the right side and that’s how I could tell which side is which. So I got a hank of black and a hank of “black widow”, which is black and red speckles (this can be seen in my previous article). I’m very happy with the results of this combo. For the pictures in this article, I used black and “urban camo”, which is black and white and grey.

I got my paracord at ParacordPlanet.com for no particular reason. Remember, 25’ of Canare cable is actually 100’ of wire that needs sleeves! It’s only $5 for 50’ of 275# paracord and we’ll buy 50’ each of black and your color of choice. That brings our grand total to $22 for 25’ worth of headphone cable and sleeving.

The last piece you need is the connectors. This will be dependent on what type of cable you want to make (single-ended vs balanced) and what headphone you’re connecting to. I’m not going to go into all the variants right now, not least because I haven’t worked with more than four or five different connectors. I’m going to discuss the two variants I have personally worked with: a balanced cable for the Hifiman HE-560 and a SE cable for the Oppo PM-3.

For my HE-560, I used a standard XLR balanced connector on the amp side, and the standard HiFiMan connectors on headphone side. Since my theme was black/black/red, I decided to get a black connector, rather than silver. Neutrik is the brand that is generally recommended as the best you can get for a reasonable price. Rean is their lower end offering and I understand they’re very nice too.

Pro tip: if you plan enough in advance, you can grab the HiFiMan connectors in bulk on eBay where you can get 10 for the same price as HiFiMAN will sell you two. They’re called SMC connectors (or possibly SMA, I’ve seen both) and there are plenty of vendors to choose from. I was very eager to get mine going so I spent more in order to get it quicker. The next time I make a Hifiman cable, I won’t make that mistake.

For the PM-3, you can’t use just any standard 1/8” TRS connector on the headphone side. It has a recessed jack so you’ll need a connector that can accommodate that. I grabbed this Eidolic connector. Not only does it fit perfectly, but it matches the color scheme of the PM-3 and the cable I am making. I decided to use the same connector on both ends so I don’t have to worry about which end goes to the headphone. To be clear, I bought two of the Eidolic connector, one for the source end and one for the headphone end.

As a final bonus, I also made a short little Balanced to SE adapter cable. It turns out that it’s perfectly fine to use a balanced headphone cable in a SE amp. All you need is a little adapter. However, if you try to plug a SE cable into a balanced amp with an adapter, you will fry your amp. You have been warned!

For my adapter, I picked up the two connectors that matched up with the black Neutrik XLR I used above: a black Neutrik female XLR and a black Neutrik ¼” TRS.

If you followed my suggestion from the previous article and put all that into a spreadsheet, you’ll see a total of about $75 before shipping. This is enough to make a balanced HiFiMan cable, a single-ended PM-3 cable, and a balanced to SE adapter, with enough cable and paracord leftover to make another cable or two depending on length. The cost could be brought down significantly by substituting cheaper connectors like Rean or Amphenol, or by ordering generic SMC connectors instead of the HiFiMan brand ones. I wouldn’t blame anyone for taking that path.

Interlude

Now comes the hardest part: the interminable wait for all your parts to come in! While you’re waiting you, might want to read up on some of the fine resources I used to get to this point.

This page right here, by a fellow named Rob Robinette, is my primary reference. I literally have this up on my phone every time I make a cable. Much of what I’ll describe further on was original gleaned from right here. This article is another one that I liked a lot because it showed great pictures of the soldering steps. It complements this article since it talks about a different method of making the cable.

Taking Things Apart

Now that your parts have arrived, it’s time to start actually putting this thing together. Ironically, the first step is to take something apart. We need to strip the four wires from out of the middle of the single cable.

Cutting the rubber sheath

Have you figured out how long you want your cable to be? For this article, I’ll assume we’re aiming for about 2 meters or approximately 6.5 feet. Because we’ll be braiding the cables, the final length will be a bit shorter than what you measure out right now. So let’s just cut off 7 feet. I haven’t figured out what the exact ratio is yet; as I said, there’s a bit of an art to this process. Measure twice, cut once.

Once we have our cut cable, we have to get the rubber sheath off. I found that the best way to do this is to use an Xacto knife and slice down the cable lengthwise. Underneath the rubber is a braided metal shield, so you don’t have to be scared of how hard you’re cutting. It will be very obvious when you hit the metal, so press hard enough to hit the metal but not go through. Slice about 6-12 inches at a time and then peel back the rubber, then repeat.

Please take care on this part to be patient and cut slowly; the cable will try to roll as you’re cutting it and you don’t want to have any accidents with your sharp new knife. Once you’ve done the whole wire, you can throw away the outer sheath.

…and slide out the bundle.

Push back the braid…

Now you should have a much thinner bundle of wires coated in a cool metal braid. There’s a really simple trick for getting the metal braid off: it basically works like a Chinese finger trap! As you push it backwards, it expands and loosens up. I use the probe from my multimeter to push back the end of the metal braid when it’s still tight. As you do so, it expands and gets easier to push back. After a second or two, you can just use your fingers to push it back enough to grab the bundle inside the braid with your other hand, and then slide the braid back. Eventually, the whole bundle in the middle will slip out and you’ll have a neat slinky braid thing that you can play with for a few seconds and then throw away.

It’s like an ogre or a parfait.

Now you’re down to a bundle of wires wrapped in a piece of thin paper. Unwrap the paper and pull it off and all that’s left is the four wires and some string. I won’t lie: this is my least favorite part of the whole process. You need to untwist all the wires and string so you’re left with just 4 wire strands and a cat toy.

Twist with your left hand while pushing towards your stationary right hand.

My method, which is not that great by the way, is to hold the bundle in my left hand and spin it while I use my right thumb and forefinger to loosely hold the end of the wires in place. As you twist with your left hand, slowly push the bundle toward your right fingers and everything unravels. After about six inches, you will likely need to make sure everything is staying untwisted on the right and get all that string out of the way. I tend to cut off the string every foot or so because it’s annoying and gets everything tangled.

Assuming you’ve avoided cutting off any fingers, getting metal splinters from the braid, and losing your patience while untwisting the wires, you should now have four 7’ lengths of 26AWG wire, two white and two blue.

Go ahead and cut your paracord sleeving now also. You’ll need two 7’ lengths of black and two more 7’ lengths of your other color. The start of the paracord will be melted to keep it from fraying and you’ll need to just cut that little melted ball off. After that, I pull the white threads from inside the paracord out completely. This will work in a very similar fashion to how you got the metal braid off. Just slide the end back a little, then grab the white threads and keep sliding the paracord back until the whole thing separates.

Everybody buddy up!

As a quick note, some people like to use this white thread to pull their wires through the paracord easily. I’ve never managed to get that to work right, but if you want to experiment with it, you’ve got nothing to lose. Otherwise, you’ll slide it through using the method detailed below.

Putting Things Together

The basic idea of this step is that you’re going to be putting the paracord sleeves onto your four wires. You’ll have two blue and two white wires, as well as two black and two colored sleeves. I recommend you split all the pairs so you end up with blue/black, blue/color, white/black and white/color. I’ll explain why later. If you forget to do this, it’s not the end of the world; don’t feel the need to re-sleeve later!

This step takes me about 10-15 minutes per wire. Put on some good tunes and lose yourself in the music to make this step one of the most enjoyable in the process.

Inching the paracord on

Take the wire in your left hand and the sleeving in your right hand. Slide the sleeve over the wire and twist the wire as you do so. This should get the first 6-12” on with no drama. From there you have to use the “inch worm” method the rest of the way. Slide some of the sleeve onto the wire with your right hand. It’ll scrunch up between your left and right fingers. Then use your left hand to slide the scrunched part down the wire. Keep repeating this until the whole wire is sleeved. Repeat for all four wires.

Pro-tip 2: if you don’t have guitar-player calluses on your left hand, you’ll probably want to wear a glove on this hand to avoid rope burn. Or don’t and build some calluses then maybe learn the guitar!

Pro-tip 3: I like to prep the wire just a bit before sliding on the sleeve. I strip a very small bit of the wire, maybe 1mm. I take the exposed copper and fold it back over. This smooths out the end a bit and makes the paracord slide on a bit easier without getting caught on anything.

What you should have now is four wires, each sleeved in paracord, looking fabulous and ready to become a cable!

To Be Continued…

All dressed up and nowhere to go

I hate to do this, but I am going to have to split this into two articles. I’ve already run this one long and I haven’t even gotten started on braiding, much less soldering. For the impatient and/or adventurous, if you read the resources I linked above, you should be able to figure out the rest of the process. For the rest, I promise to be back soon to walk you through the final steps.

I welcome your feedback in the comments below. This is as much a journey for me as it is for you and I bet some of you have techniques to share that will make all of us better DIY-ers! I am looking forward to reading about your color choices too. I know at least one of you is planning on going full pink. I hope to see you next time, dear reader.

Reply

Reply

Reply

Reply

Want to join discussion?

Feel free to contribute!